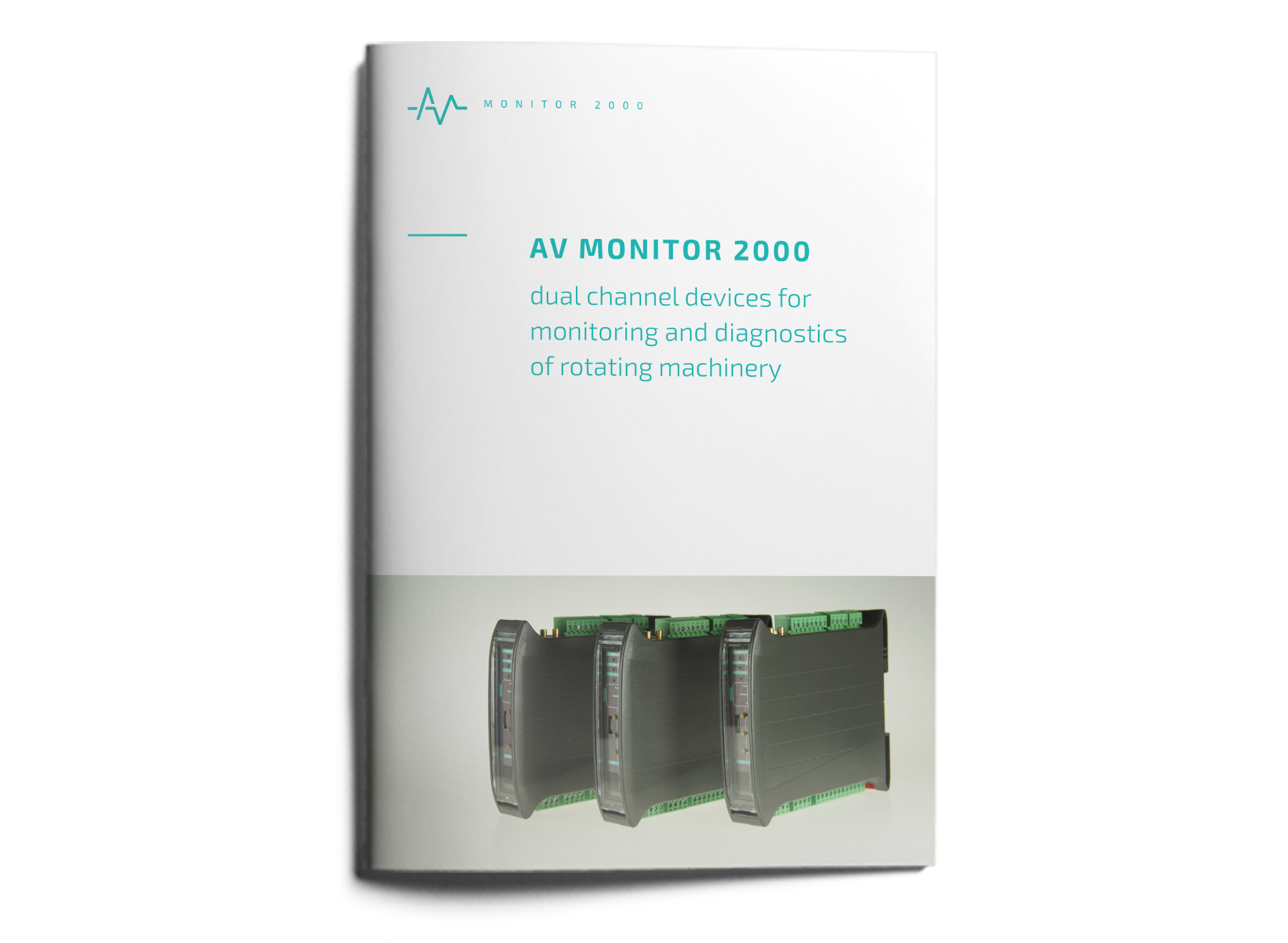

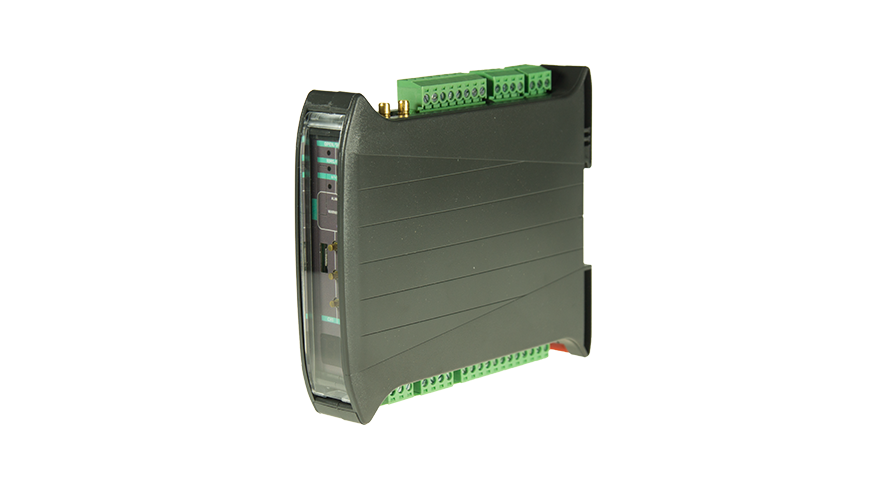

AVM 2105DV module has all AVM 2105D functionalities, and also enables to calculate energy in 8 defined frequency bands, in which it is possible to set warning/alarm thresholds and assign relay outputs.

AVM 2105DV

rotationary machines monitoring and diagnostic module with damage localisation function

AVM 2105DV

Applications

Energy calculation in the band enables to locate damage, meaning it is possible to indicate specific gear stage, or damaged bearing. AVM 2105DV allows to save calculated estimates/analysis to a SD card in predifined time intervals.

Technical data

| Inputs | 2 x IEPE |

|---|---|

| Outputs | 5 x relays (NO, NC) |

| SD card save | YES |

| Measured values | Acceleration |

| Damage detection | YES |

| Damage localisation | YES |

| Application | Rotationary machines: ventilators, pumps, compressors |

| Damage examples | bearing damage, unbalance, cavitation |

Available estimates

| Acceleration/velocity RMS | YES |

|---|---|

| Acceleration/velocity 0-Peak | YES |

| Envelope | YES |

| Energy in bands | YES |

| Revolution periods | – (available in AVM 2105DK) |

| Order analysis | – (available in AVM 2115DA) |

| Amplitude analysis | – (available in AVM 2115DA) |

Specification

| Input type | 2 x IEPE |

|---|---|

| Power supply | 24 V DC (18-32 V DC) |

| Power consumtion | < 4 W |

| Isolation | 1 kV |

| Operational temperature | -20 °C… +80 °C |

| IP Code | IP20 |

| Low-power relay outputs status/warning/alarm | 4 x relay outputs: – a type of contacts: NC lub NO |

| 4-20 mA output | 2 x electrical outputs 4-20 mA – electrical circuit output from +7 VDC to +36 VDC |

| AC voltage output | 2x voltage output – buffer – connected vibration sensors, enabling to connect advanced vibration analyzer, e.g: MTN/VM330D |

| Panel | – 2 x 8-segment LED display |

| Dimensions | 23 mm x 100 mm x 120 mm (L x W x H) |

| Mounting | 35 mm DIN rail |

Contact

Interested in our offer?

Write to us