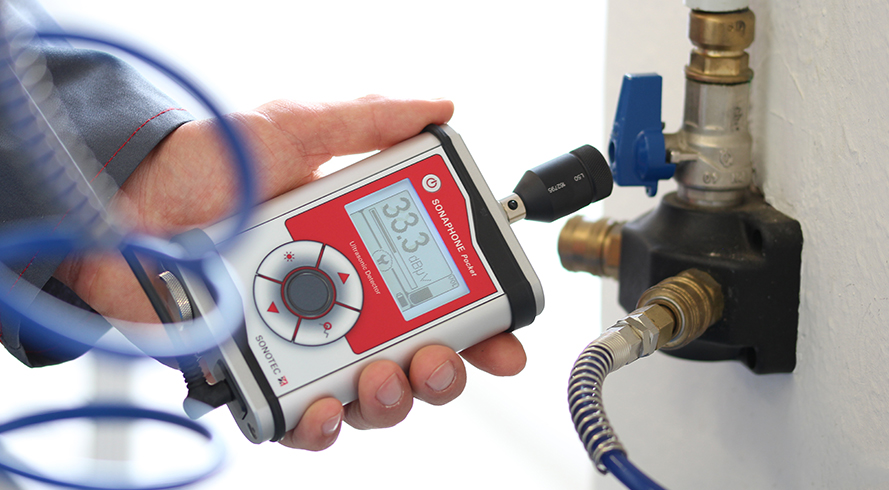

Numerous preventive maintenance tasks can be handled quickly and efficiently with the SONAPHONE Pocket. Lower your energy costs and increase your operational safety with the most compact testing device of the SONAPHONE series.

SONAPHONE Pocket

compact ultrasonic testing device for preventive maintenance

SONAPHONE Pocket

Applications

The ultrasonic testing device is used for

- leak detection with compressed air, gas and vacuum systems,

- wear control on rotating machines,

- providing evidence of partial electrical discharges where there is insulation damage,

- functional testing of steam traps and valves and

- tightness testing of unpressurised systems.

With the SONAPHONE Pocket, you identify problems even before they arise and create value at all levels of your company. Just by detecting and eliminating leaks, you can reduce the energy costs for your compressed air system by up to 30 per cent. This also has positive effects on your operational safety and system productivity through early warning of bearing failure and evidence of partial electrical discharges.

The compact testing device is designed to fit in any pocket. However, its robust construction means it is also appropriate for harsh industrial environments. The SONAPHONE Pocket is supplemented by extensive accessories in the form of airborne and structure-borne sound probes. You will receive the appropriate probe for your application from our product range, which you can attach to the device with just one simple movement.

You do not need much time or expensive training to perform the test procedure. The testing device makes the ultrasonic signals audible and shows them on a digital display at the same time. The SONAPHONE Pocket is easy to handle and very effective.

Features

- find leaks and save energy

- early warning of bearing failure

- compact design

- easy to use

- extensive accessories for a wide range of applications

Technical data

| Transmission frequency | 40 kHz +- 2 kHz |

|---|---|

| Functionality | Detection of ultrasonic signals: Makes the ultrasonic signals audible and shows them on a digital display; Auto-power-off-function |

| Display | LC-Display with illuminated background |

| Connections | For different ultrasonic probes Stereo jack socket |

| Power supply | 2 AA batteries or accumulators |

| Operating time | Approx. 24 h |

| Dimensions | 85 x 130 x 30 mm |

| Weight | Approx. 280 g |

| Temperatura pracy | od -10 do + 60 °C |

| Operating temperature | -10 °C – +60°C |

| Storage temperature | -20 °C – +60°C |

| Protection class | Device: IP54; Probe: IP20 |

| Accessories | Probes, headphones, carrying strap, carrying case, instruction manual |

Accessories

- Leak Detection Set

incl. airborne sound probe, directional tube with tip, acoustic horn

- Air-borne probe L 50

Applications: leak detection, proof of seal failures - Contact Probe L 51

Applications: inspection of valves, slides and safety valves - Contact Probe L 52

Applications: testing of steam traps, inspection of rotating machines - Flexible air-borne sound probe L 53

Applications: leak detection at places, difficult to access - Parabolic Dish SONOSPOT

Applications: precise detection of leaks or partial discharges over long distances - Spherical Transmitter SONOSPHERE for SONAPHONE T

Accessories: stand, magnetic and suction holder applications: leak testing of cabins and containers (in combination with SONAPHONE T and SONAPHONE Pocket) - SONAPHONE T

Adjustable Ultrasonic Transmitter for the Reliable Detection of Leaks

Contact

Interested in our offer?

Write to us