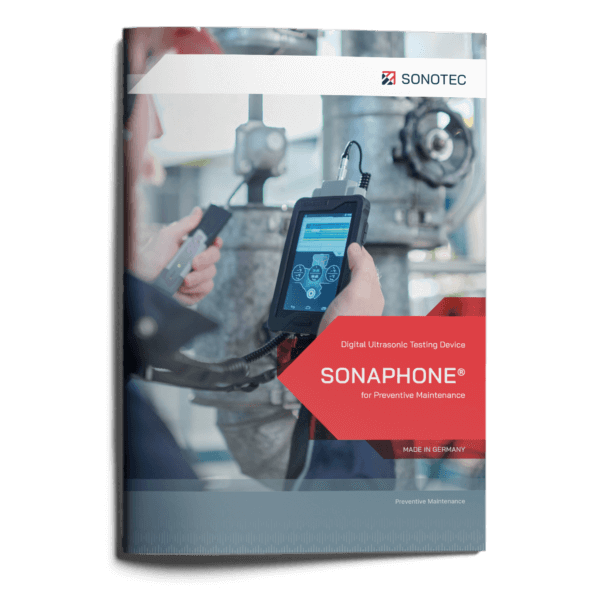

In the age of Industry 4.0 the optimizing processes, increasing operational safety, and improving energy efficiency are becoming more and more significant. Meet the challenges of Maintenance 4.0 with the new SONAPHONE from SONOTEC. The digital ultrasonic testing device combines innovative sensors and software for preventive maintenance that can be operated intuitively and paves the way for new processes for new applications.

SONAPHONE

ultrasonic testing device for maintenance 4.0

SONAPHONE

Applications

With the new SONAPHONE you can

- detect and classify leaks in compressed air, gas and vacuum systems and reduce your energy costs,

- monitor the condition of your machines and determine the optimal maintenance time,

- identify leaks in windows, doors, vehicles, components and containers and ensure compliance with specified quality requirements,

- find electrical partial discharges and insulation damage and increase your operational safety,

- assess the function of steam traps and prevent energy and steam loss and damage to the steam system

Features

- new applications through new processes

- user-friendly interface speeds up your inspection process

- record ultrasonic frequencies from 20 to 100 kHz

- store test data and spectrograms

- add photographs, voice memos and comments to the measuring point

- create test reports with a few clicks

- minimize downtimes and increase operational safety

- improve energy efficiency

Technical data

| Device design | Digital ultrasonic testing device |

|---|---|

| Display | 5″ TFT-Display with multi-touch controller |

| Acoustic output of signals | Via loudspeakers or wired headphones |

| Dimensions (W x H x D) | 90 x 174 x 25 mm |

| Weight | 370 g |

| Temperature range |

|

| Battery |

|

| Connectors and interfaces |

|

| Protection class | IP40 |

| Memory |

|

| Standards and directives |

|

Media

Contact

Interested in our offer?

Write to us